BSG Waste Material Project

The Brief:

Create a second usage for a random waste material that is selected. Each group has the option to choose an easy, medium or hard material.

Factors such as marketing, production costs and material characteristics should be considered.

By the end, a report of your research on your material and the new design should be made, along with a video outlining the details of your product.

For this project, our team decided to challenge ourselves, and thus, we selected material from the 'hard' pile. In the end, we got the material Brewers Spent Grain (BSG), which is a byproduct of beer after the brewing process.

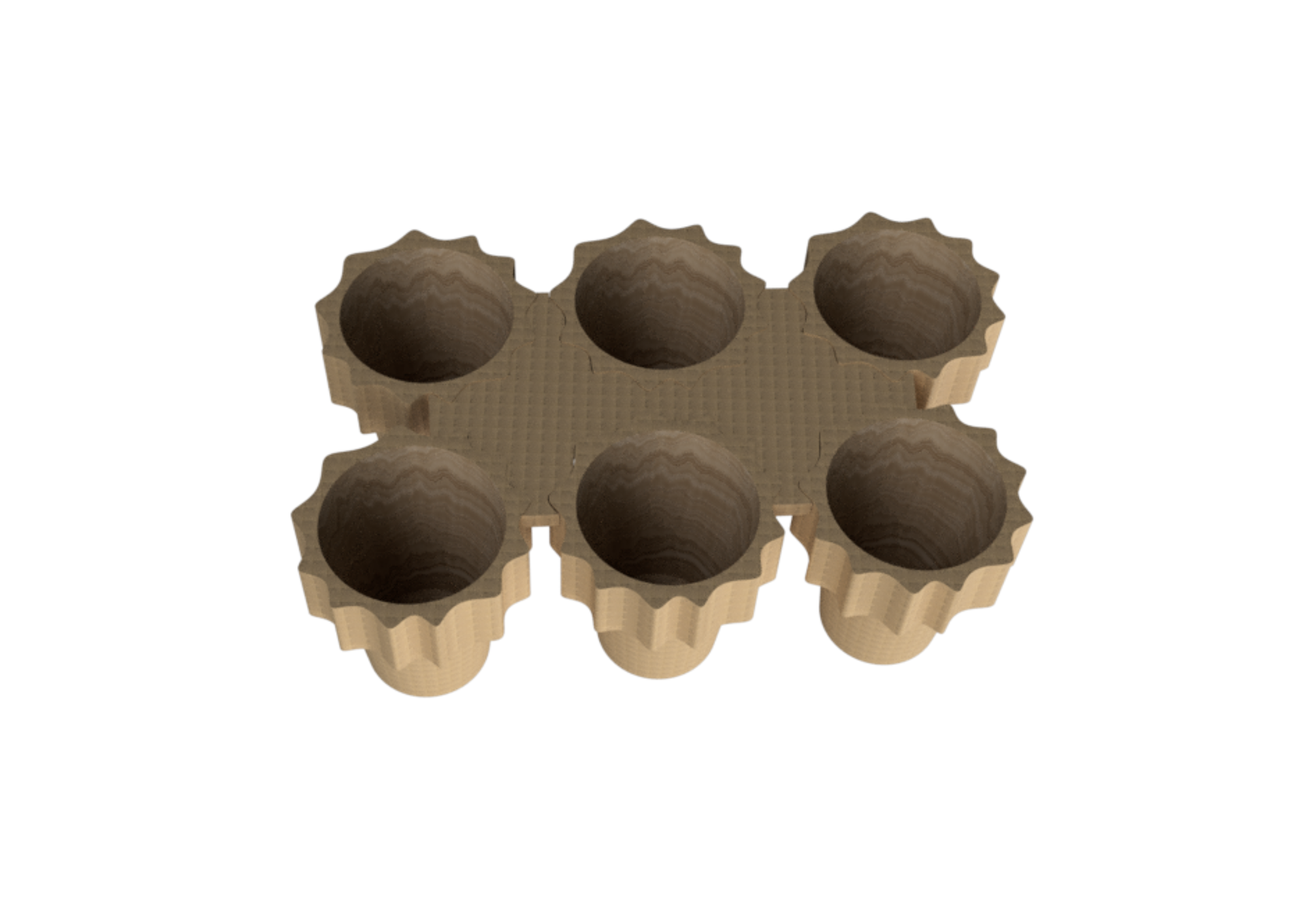

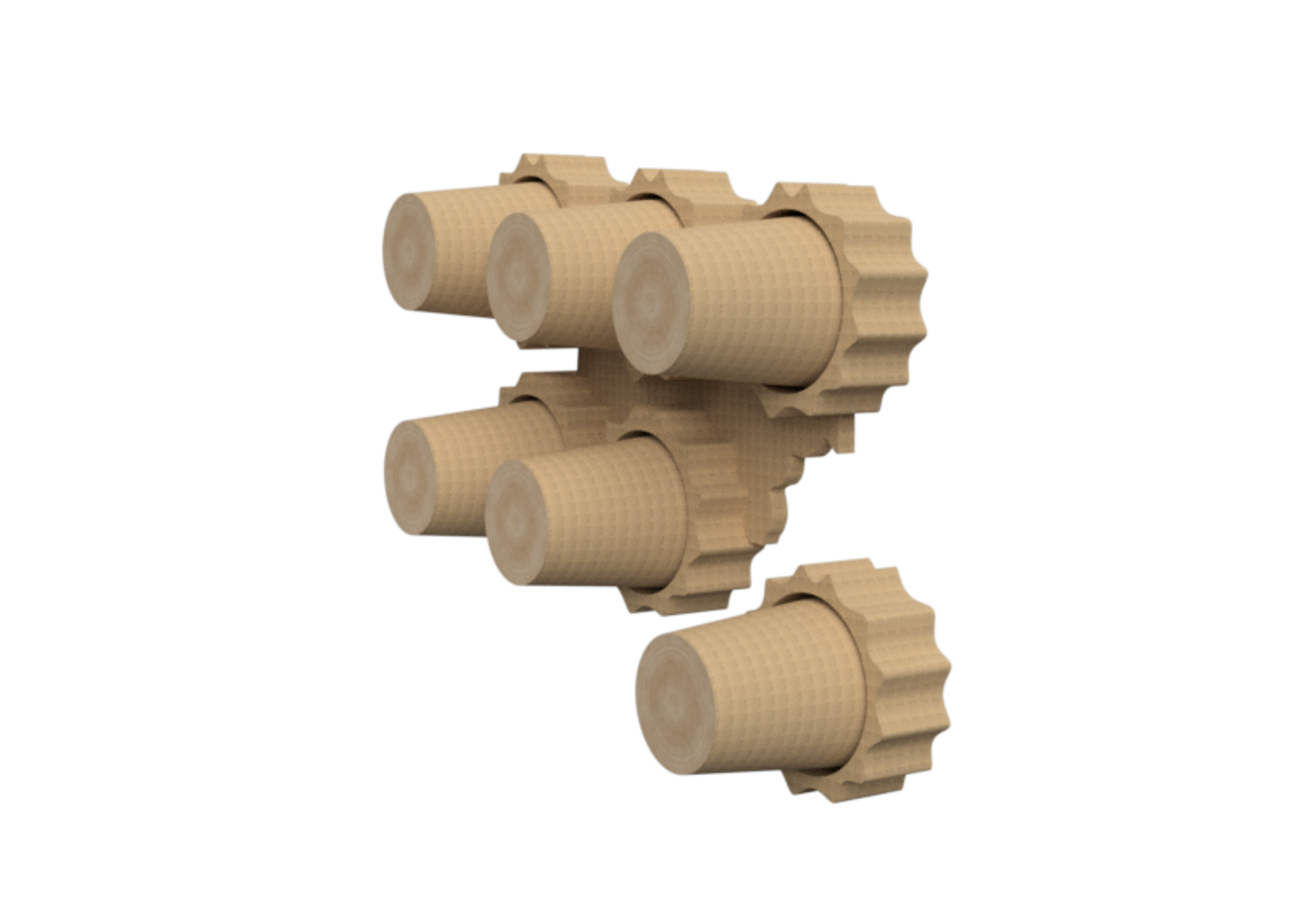

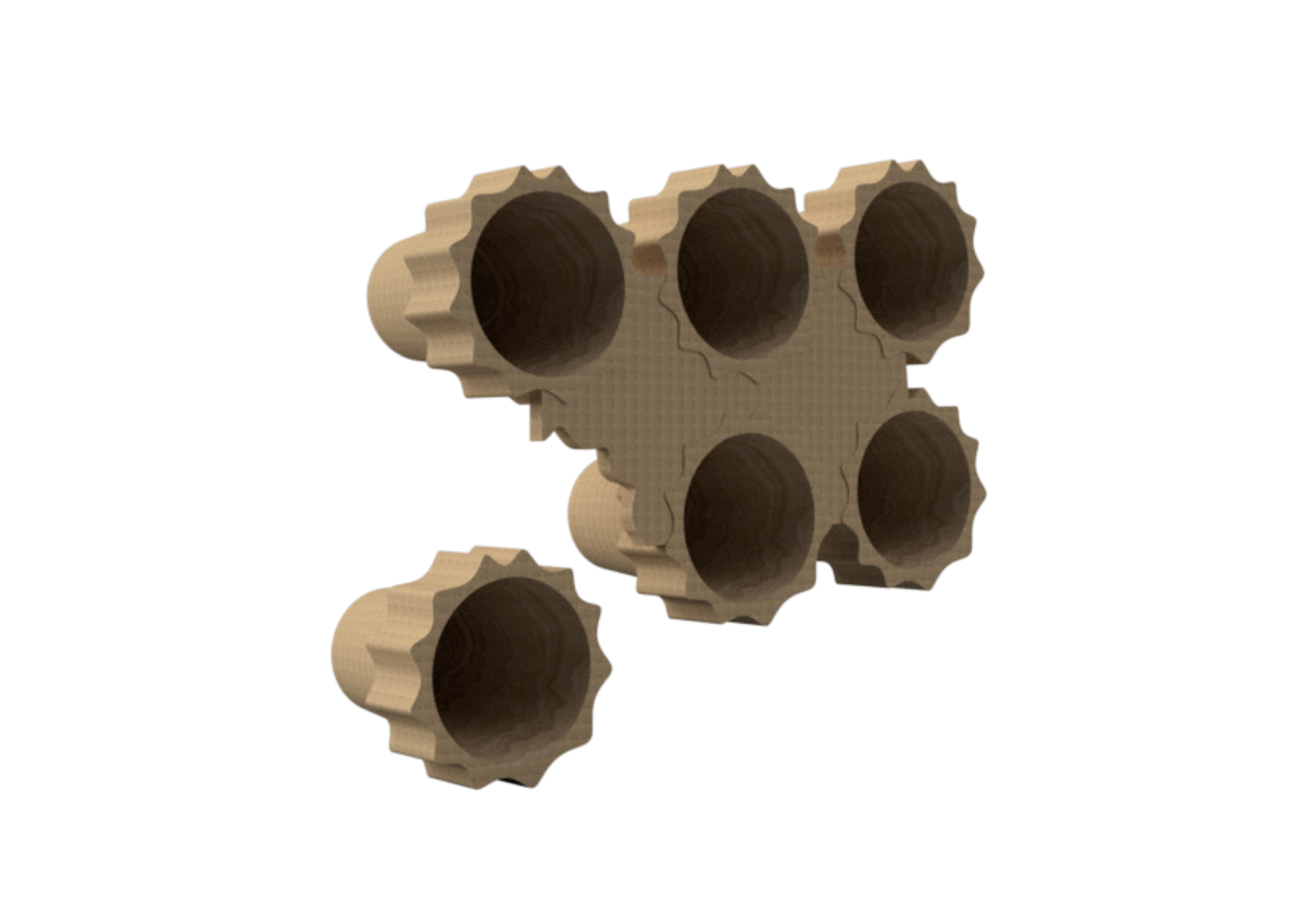

It is a natural material that is compostable, however, with the excessive amount of material left over our group realised that more people needed to invest in this product. Therefore, we created the 'compostable pot plants'.

The purpose of this product is to care for plants inside when they are young, then place the pot plant directly outside into the garden, where the BSG can then be served as compost. By doing so, our group hopes that more people will use this product, especially as home gardening interests are increasing.

Note: For more research about BSG, and the processes that took place to help create this product, please get into contact me

The process that we decided to utilise was a process called paper pulp.

Through research, it was identified that BSG has similar properties to paper. Because of this, our team decided to use this process to try and create our compostable pot plants.

In order to try this method, we went into the laboratory to apply this.

The first thing that we did was grind up the BSG with some water. This was to ensure that we could get the grains to have a finer consistency.

We then placed the mixture into a bucket and grabbed a handful of the grains.

This was then followed by the process of placing it into a cheesecloth to remove the remaining water in the mixture.

Afterwards, we then applied some PVA to the grains, making sure to mix it well into the mixture. This is to ensure that later once the grain has dried, it can stay together. Initially, due to the lack of resources, we first tried it out with PVA glue, however, the idea, in the end, was to use potato starch or rice paste, which would act as a natural adhesive.

And lastly, it was placed into a mould.

Once dried, we were then left with the final product.

In our initial test, we progressed to the stage of pouring our mixture into the mould. However, due to New Zealand's lockdown in early 2020, we were unable to observe the results. This delay allowed us to focus on further refining the product through research to ensure its effectiveness.

From a marketing perspective, our goal was to make this product freely available. Based on first-hand research, we discovered that most brewers were eager to dispose of their spent grain at no cost, making it an extremely affordable raw material. Additionally, with beer ranking as one of the world's most popular beverages after water and tea, the availability of brewers' spent grain is ample. These factors supported our decision to provide this product free of charge, encouraging individuals to produce it themselves.

We also explored partnerships with supermarkets such as New World, leveraging initiatives like their "Little Garden" promotions to reach gardening enthusiasts. Gardening has seen a surge in popularity, particularly during the COVID-19 pandemic, with more individuals cultivating home gardens, whether in small boxes or larger spaces. This growing trend strengthens our confidence in the product's potential for success.

Our Brewers' Spent Grain (BSG) compostable pot plants are designed to provide essential nutrients to gardens while supporting users in nurturing young plants. Made from upcycled brewers' spent grain, this eco-friendly product is cost-efficient, safe, and readily available. Our team is proud to have developed a solution that positively impacts the environment by reducing waste and promoting sustainable gardening practices.

Here we have a quick video summarising out product

Reflection:

I found that this project was difficult, yet very enjoyable. The process of researching and utilising the newfound knowledge was something that I found highly rewarding. This project had just the right amount of both science and design and for someone who highly enjoys the research sections of a project, I found that I was constantly working on this project without realising that time was passing. Initially, I was quite unfamiliar with the task, and therefore, I found that I was quite stressed with this project, however, after taking some time to research and understand the material, I soon found myself enjoying the task at hand. Whether it was researching, designing or assisting with the video, I could see that at every point of this assignment, I was enjoying the process.

If there was one thing that would help this project run better, it would be to test the product personally. I strongly believe that if we were able to work on this assignment again, then we would be able to observe the problems first-hand and work on specific sections to help improve the product. Whether it is to add my adhesives, or to include more water into the mixture, I believe if we had more time in the lab, we would be able to create a more reliable and efficient product.

Because I was enjoying the process of the project, I never realised how much work I was doing. It was not until the very end, that I found myself to be low on energy, due to over-exertion. Nonetheless, I still found that the end outcome was very rewarding, and all the work that our group put in was worth it.

Skills Obtained:

- Research

- Ideating

- Conceptualising

- Leadership

- Zoom

- PowerPoint

- 2D Animation

- Video Editing

- Voice-Over

- CAD (Fusion360)